Main technical requirements for the production of checking fixture

1 The design, manufacturing and acceptance of the checking fixtures shall be based on the product drawings and 30 data. Meet the requirements of technical documents and other relevant checking fixture technical negotiation contents. In case of any discrepancy between the product drawing and 30 data, Party A’s written notice shall prevail.

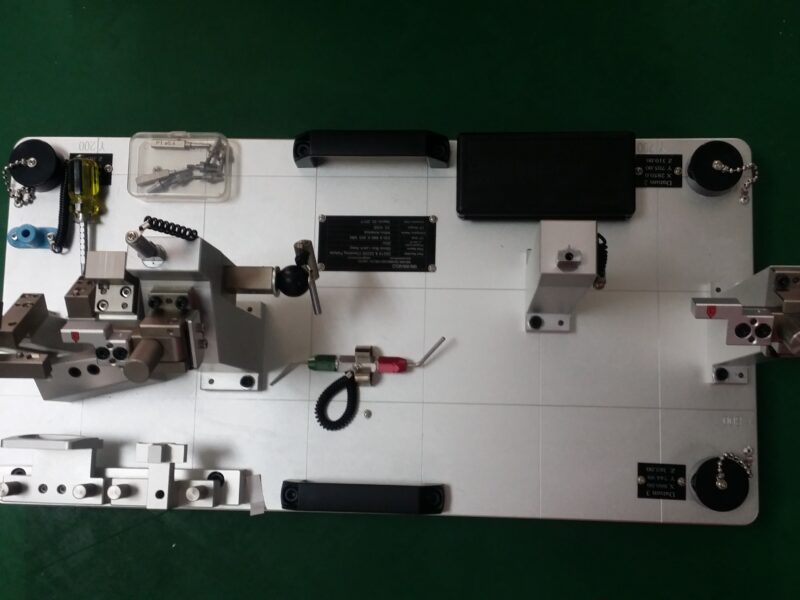

2 The checking fixture scheme shall specify the number and position of datum holes, datum planes and locating surfaces, the number, position and pressing method of pressing points, and determine the testing method and the testing requirements for various sections and flanging surfaces, and shall be illustrated with a sketch.

3. The structure of the checking fixture: ① It should be optimized and reasonable to check the overall shape, contour curve, position of each hole and other important parts of the stamping parts, and it should be accurate, reliable and easy to operate. ② The size and quality of the checking fixture shall be as small as possible under the condition that the inspection has sufficient strength and rigidity, and the checking fixture shall not be deformed. ③ The structural design of the checking fixture can ensure that the parts can be inspected manually, and the operation is convenient.

4 Requirements for the designed clearance value of the checking fixture: ① The clearance value of a single checking fixture is 3mm. ② The clearance value and height difference value of the measuring part of the checking fixture shall be marked on the checking fixture with an indelible mark or a label.

5 The lifting device, clamp, special gauge and other parts shall not protrude out of the base when placed in storage and in working condition.

6 It must be ensured that the checking fixtures and their corresponding molds and welding clips have the same service life under normal use frequency and good maintenance.

7 Three coordinate measurement must be adopted for mortar inspection and pre acceptance of checking fixtures, and the equipment accuracy is higher than 0.02mm. The equipment is required to be calibrated every six months or one year. One week before the pre acceptance, the manufacturer shall provide the calibration report for the last six months or one year. The equipment calibration must be equivalent to or above the provincial metrological institution in China.

8 The checking fixture manual must be fixed on the checking fixture and ensure that it will not be damaged during the service life of the checking fixture.