Classification and role of machine tool fixtures

Classification according to the scope of application of fixtures

(1) General-purpose fixture

General-purpose fixture refers to the structure has been standardized, and has a large range of fixtures, for example, the lathe with a three-jaw chuck and four-jaw chuck, milling machine with a flat vise and indexing head.

(2) special machine tool fixture

Special machine tool jigs are specially designed and manufactured for a certain process of a workpiece. Special machine tool jigs are suitable for relatively stable products and large output applications.

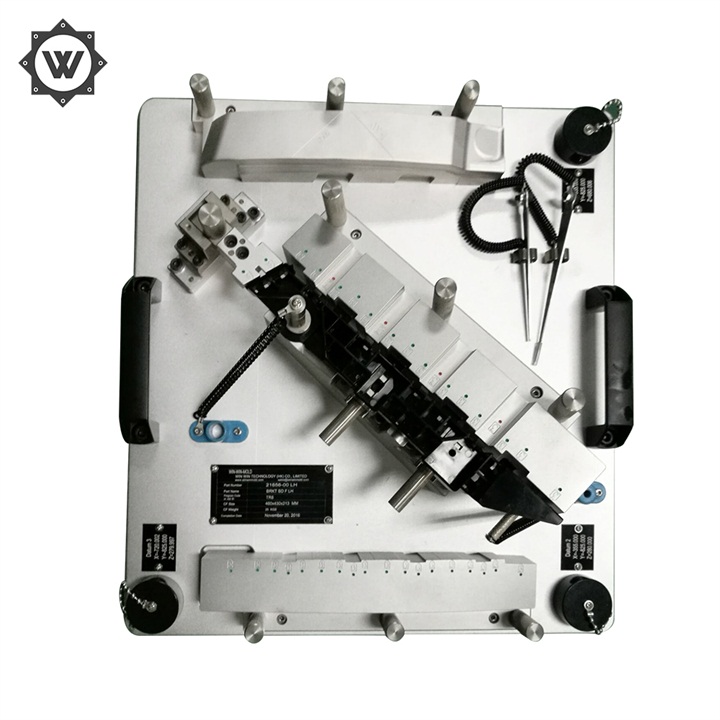

(3) Combination fixture

Combination fixture is a fixture assembled by a set of pre-made standard components and joint parts. Combination fixture structure is flexible, design and assembly cycle is short, fixture parts can be reused for a long time, suitable for multi-variety single-piece small batch production or new product trial production and other applications.

(4) Group fixture

Group jigs are designed and manufactured for each part group when group processing is used. When changing to process another part in the same group, it is only necessary to adjust or replace individual components on the jig to carry out processing. Group fixture is suitable for application in multi-species, small and medium batch production.

(5) Follow-Up Fixture

It is a mobile fixture used on the automatic line, before the workpiece enters the automatic line processing, the workpiece is first installed in the fixture, and then the fixture along the automatic line with the workpiece to be processed from one workstation to the next in turn, until the workpiece in the exit from the automatic line processing, the workpiece will be removed from the fixture. A follow-on fixture is a fixture that always moves along the automatic line with the workpiece.

Classification by type of machine tool used

Different types of machine tools have different jig structures, thus the jig can be classified into lathe jig, drill press jig, milling machine jig, boring machine jig, grinding machine jig and combination machine tool jig.

Classified by the power source of the fixture

According to the clamping power source used in the fixture, the fixture can be divided into manual clamping fixture, pneumatic clamping fixture, hydraulic clamping fixture, gas-hydraulic linkage clamping fixture, electromagnetic fixture, vacuum fixture, etc.

The role of machine tool fixtures

(1) to ensure machining accuracy

Clamping workpiece with machine tool fixture, can accurately determine the relative position between the workpiece and the tool, machine tool, can ensure machining accuracy.

(2) Improve production efficiency

Machine tool fixtures can quickly position and clamp the workpiece, which can reduce auxiliary time and improve productivity.

(3) Reduce labor intensity

Machine tool fixtures using mechanical, pneumatic, hydraulic clamping devices, can reduce the labor intensity of workers.

(4) expand the scope of the machine tool process

The use of machine tool fixtures can expand the processing range of the machine tool, for example, the use of boring die in the lathe or drill press can replace the boring machine boring, so that the lathe, drill press has the function of boring machine.