Design basis of automobile checking fixtures

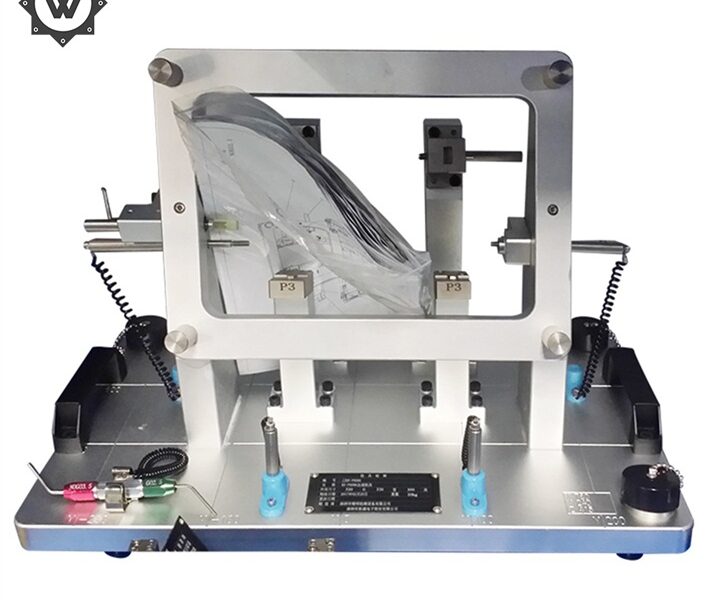

Our checking fixtures can become an important reference for customers to debug products. The fundamental reason is that our checking fixtures are designed according to the drawing tolerance of customers’ products. The checking fixture on the checking fixture go no go gauge trimming gauge, etc

Auto checking fixtures serve auto parts. Now more and more parts manufacturers use checking fixtures to debug products, so the functionality of checking fixtures is becoming stronger and stronger, and checking fixtures have become an important reference for customers to recognize parts.

Our checking fixtures can become an important reference for customers to debug products. The fundamental reason is that our checking fixtures are designed according to the drawing tolerance of customers’ products. The go no go gauge, trimming gauge, etc. of the checking fixtures on the checking fixture are all one-to-one corresponding to the tolerance on the product drawing, that is, if the product can meet the measurement of each checking fixture on the checking fixture, then the product can also meet the requirements of the product drawing.

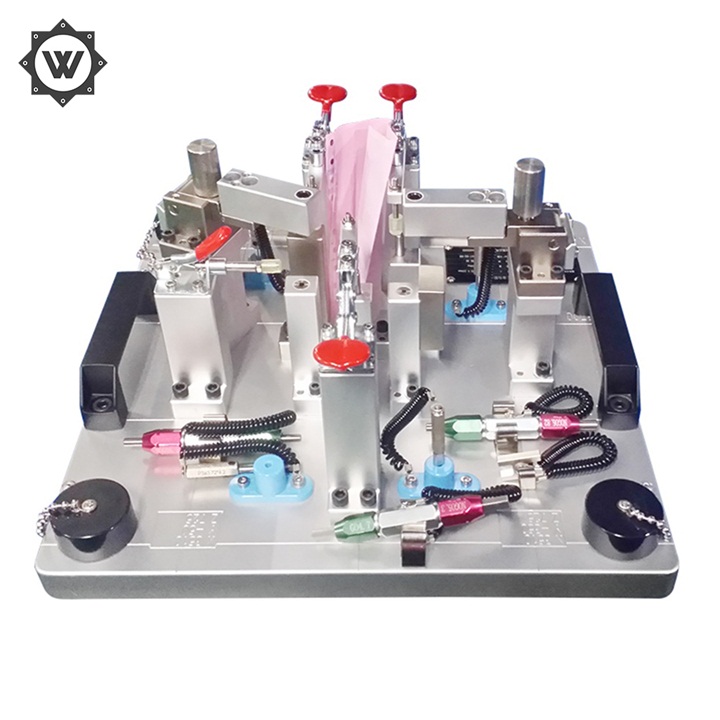

The design basis of automobile checking fixtures is mainly product drawings, which are provided by customers. The checking fixture company designs checking fixtures according to the tolerance of drawings.

The design basis of the automobile checking fixture is the style book, which is generally provided by the customer. The style book will indicate the detection method and location.

The design of automobile checking fixtures is based on the customer’s needs. When the product drawings conflict with the customer’s needs, our checking fixture design standards should take the customer first.

As a qualified checking fixture design, we should ensure that the inspection we design has evidence to rely on, and we should not design without foundation, which is irresponsible to ourselves and customers.