Five Principles and Design steps of checking fixtures

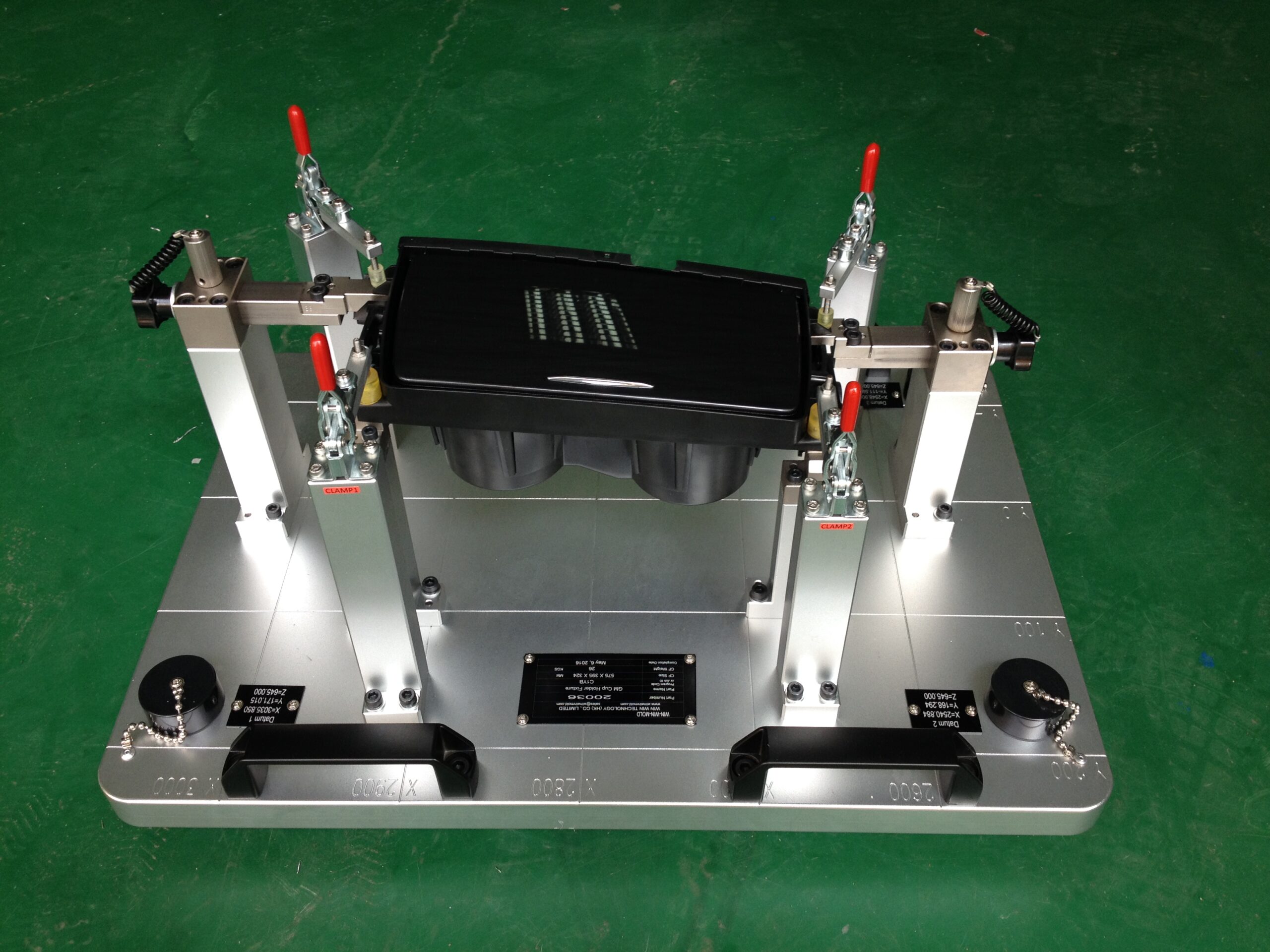

1. Have and be able to realize the benchmark of checking fixture processing and testing, including processing benchmark and measurement benchmark, which can be used for later modification and regular calibration of checking fixtures;

2. It has a constant and accurate positioning reference to ensure maximum repeatability and reproducibility;

3. Low manufacturing cost, wear resistance and stability;

4. Convenience of operation, including taking, placing and testing of products, operation and handling of clamps;

5 The detection function can meet the requirements of product quality control and the analysis function of product and process quality.

Design steps of checking fixture

1 Digest in the early stage, and define the product requirements, including the positioning reference position and size, inspection characteristics, measurement position and tolerance size;

2 Determine the structure type of the checking fixture according to the product requirements;

3 Determine the measurement method and form a conceptual diagram or schematic diagram of the gauge design;

4. Prepare assembly drawings and part drawings. The assembly drawings must reflect the positioning datum, inspection methods of inspection features, fit dimensions, overall dimensions, part materials, heat treatment requirements, etc.