How to maintain the automobile checking fixtures?

How to carry out maintenance of automobile checking fixtures? At this stage, with the gradual improvement of the design and accuracy of automobile checking fixtures, many automobile checking fixtures need to be fully maintained to increase their service life.

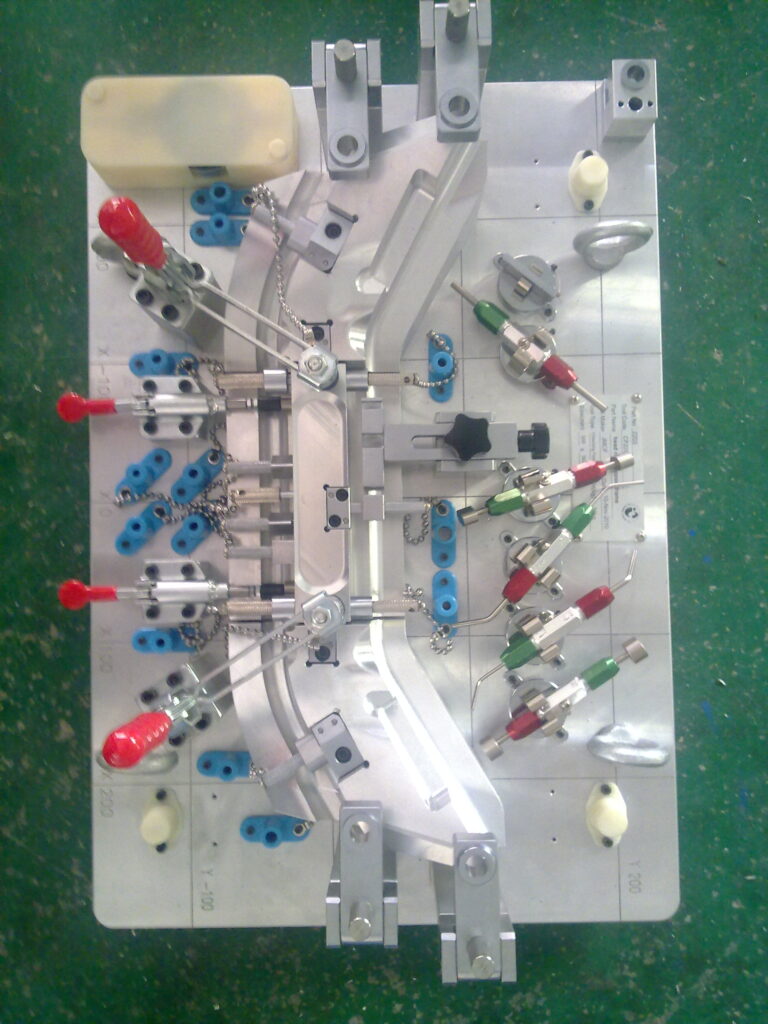

1. Basic maintenance of automobile checking fixtures: ensure that the exterior of the analog block of the checking fixture is clean, and pay attention to the position of some soleplates, pins and their detection pins; Put the movable parts to be disassembled on the corresponding positions. 2. Keep the environmental factors of the automobile checking fixtures dry: the storage temperature of the automobile checking fixtures should be between – 10 ℃ and 60 ℃; The humidity should be below 60 degrees; The particles must not exceed 2 per cent.

3. The maintenance time can be divided into six months or once a year:

(1) Check whether the pin hole is damaged, and replace it immediately in case of any problem;

(2) Check whether the precision slideway is loose, and add lubricating oil immediately;

(3) Immediately check whether the scribing scale and coating have fallen and been damaged;

(4) Check whether the positioning datum is rusted or damaged. If yes, replace or polish it immediately;

Carry out maintenance according to the methods mentioned above to ensure that your automobile checking fixtures will not have big problems. Better maintenance can promote the improvement of work efficiency. Unlike other checking fixtures, the high-precision performance of automobile checking fixtures cannot cause any wear and tear. Therefore, store your checking fixtures and products carefully.