Knowledge of automotive gauges

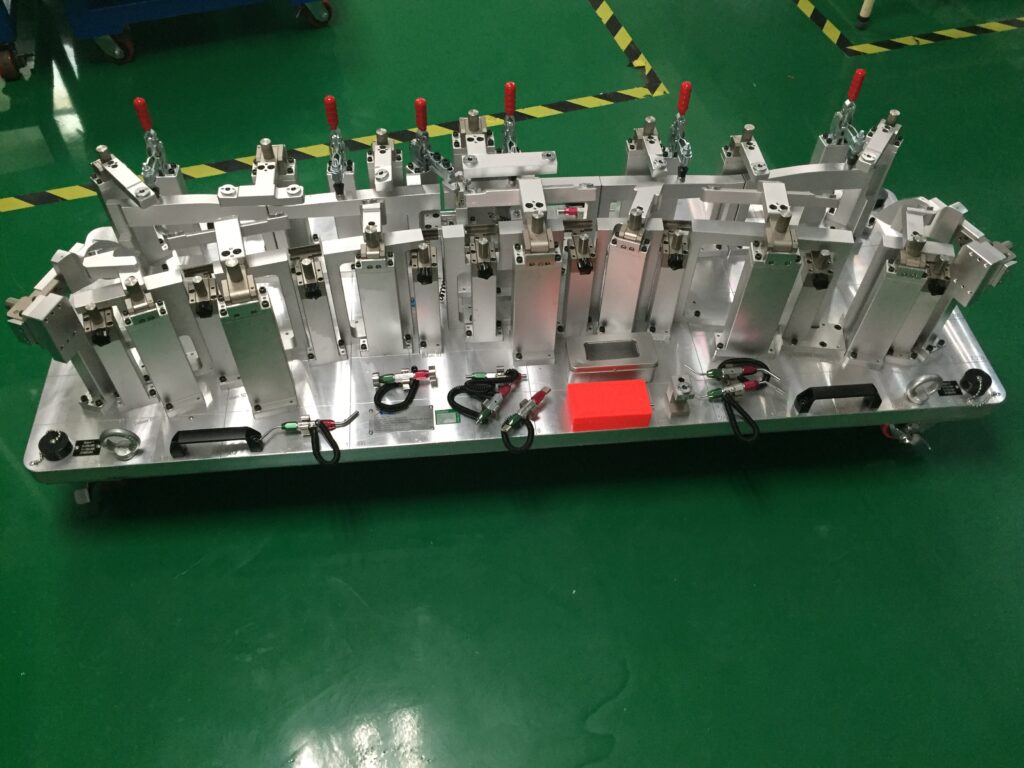

checking fixture overview: definition of checking fixture (measurement bracket)

- Gage is a special inspection equipment used to measure and evaluate the dimensional quality of the parts.

- In the parts production site, through the gage to achieve online inspection of the parts, for which the parts need to be accurately mounted on the gage, and then through visual inspection, or measuring table, or calipers on the parts surface, around the inspection, but also with the help of inspection pins or visual inspection of different nature of the parts of the holes and parts and parts between the joint position for visual inspection, so as to ensure that the production of parts to achieve rapid judgment of the quality state In this case In this case, the visual inspection or measurement allows to determine: the deviations between the size and shape of the area around the part contour and the relative position and the theoretical values of the gauges machined directly by CAD/CM.

- For some extremely important functional dimensions on the part, numerical inspection can also be performed with the use of gauges. Usually the exact coordinates of the part based on the body coordinate system cannot be obtained directly with the help of the gage, but only by placing the part on the gage and measuring it with a CMM. The structure of modern inspection gauges is designed to be used as a measuring stand at the same time. However, when the online inspection function of the gage and the function of the measuring stand cannot be satisfied at the same time, the online inspection function of the gage should be satisfied first.

- The measuring support is a kind of auxiliary support when measuring parts with CMM, all of its support surface (point) and positioning reference surface (point) must be milled according to the CAD data of the parts, some special parts of the measuring support should also have part of the function of the checking fixture.

The design of the gage must be in accordance with the final 3D data and 2D drawings provided by the customer, the 3D data must have the correct automotive coordinate system, the design and manufacture of the gage need to be approved by the customer before processing and delivery.