Main functions of special fixture

The special fixture is specially designed and manufactured to meet the processing requirements of a certain process of a workpiece. Its functions mainly include the following aspects:

1. Ensure the position accuracy of the machined surface of the workpiece.

For example, the distance precision, parallelism, coaxiality, etc. with other surfaces. For workpieces with complicated laymen and high position accuracy requirements, it is often difficult to meet the accuracy requirements when using universal fixtures for machining.

2. The working procedure time is shortened, thereby improving the labor productivity.

The time required for a certain process, which mainly includes the mobile time required for processing the workpiece and the auxiliary time required for loading and unloading the workpiece.

With the use of special fixtures, the work of installing workpieces and switching stations can be greatly simplified, and no line drawing and alignment are required, which shortens the auxiliary time of the process and saves the process of line drawing, thus improving labor productivity. In production, due to the use of a fixture for parallel processing of multiple workpieces, the mobile time of several workpieces processed at the same time will be the same as that of one workpiece. The rotary multi station continuous machining fixture can be used to process a workpiece while loading and unloading other workpieces, so that the auxiliary time coincides with the mobile time. In a word, with the adoption and further improvement of special fixtures, the process time can be effectively shortened to meet the needs of continuous development of production.

3. The use of special fixtures can also expand the process range of the machine tool.

For example, after adding a boring jig to an ordinary lathe, it can work instead of the boring machine; After the special fixture is installed, the formed surface can be turned to give full play to the role of universal machine tools.

4. Reduce labor intensity and ensure safe production.

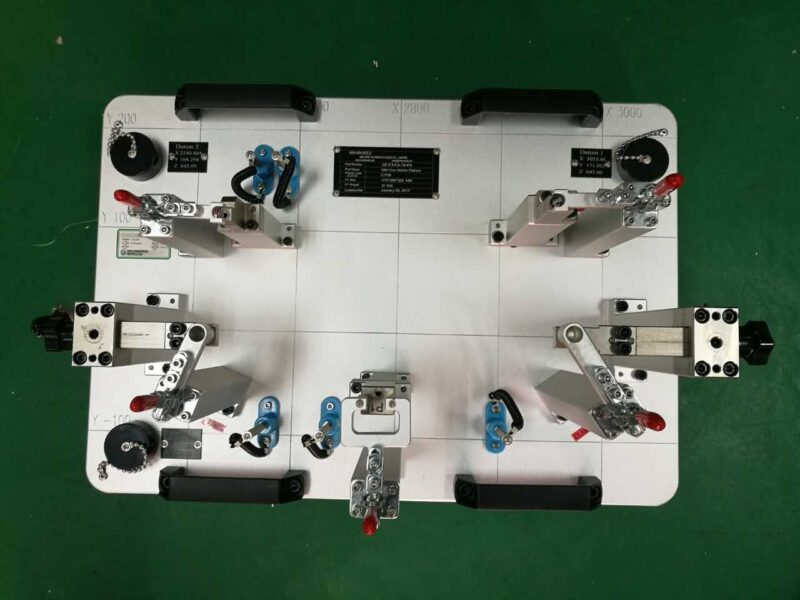

According to the production needs, the use of some pneumatic, hydraulic or other mechanized special fixtures with a high degree of automation plays a great role in reducing the labor intensity of workers, ensuring production safety and the stability and high yield of products. When machining large workpieces, such as the screw holes on the lower and upper sides of the lathe bed, it is necessary to turn the workpieces on the bed several times for processing, which is labor-intensive and unsafe. After using electric rotary drilling machine furniture, it can achieve the purpose of improving production efficiency, reducing labor intensity and ensuring production safety.

Special fixture plays a very important role in production, so should it be designed and adopted in any occasion?

This problem is a concrete analysis of specific problems. The role of special fixtures in production mentioned above is only one aspect of things. On the other hand, the design, manufacture and materials of the fixture must consume certain expenses, which increases the cost of the product. Therefore, it is a big problem in which case it is economical to use what kind of fixture, especially for major special fixtures with large design and manufacturing workload, which should be jointly studied and solved with workers and other masters.

Things are always divided into two, and special fixtures also have shortcomings, that is, the contradiction between the specificity of special fixtures and product diversity. As the special fixture is only applicable to a certain process of one workpiece processing, the number of fixtures is also rising with the continuous increase of product varieties, resulting in difficulties in storage and management; When a product is no longer produced, the original fixture is generally unable to be reused, resulting in waste. At the same time, the design and production period of special fixture is long, which also contradicts the rapid development of production. However, in the current mass production of machinery plants, most of them still use universal machine tools and special fixtures for machining the workpiece.