Modular design method for non-standard parts of machine tool fixtures

Most of the parts involved in fixture design are national variation parts or enterprise standard parts, but there are still some non-standard parts without standards, which are small in number but not small in workload.

In order to give full play to the advantages of CAD technology, modular design must be carried out for this part of the parts. For these non-standard parts of the fixture, the module is divided according to the functions accomplished, and the parameterization is carried out according to the longitudinal series module system.

1、Design of basic model

How to determine the basis of the series module is the key to modular design. The design of non-standard parts is characterized by arbitrary, and it is difficult to extract a representative base model from millions of design drawings, and the correct selection of such.

(1) Extensive and detailed collection of information and investigation on fixture non-standard parts to find out the representative base type information.

Get from these information; get from fixture design experts in the form of enlightenment or questioning; get from the use site by going deeper into the site and listening to the opinions of the use personnel.

(2) Classifying and organizing a large amount of disorganized information is the key to the selection, and determines the coverage of the selected model.

(3) The selected basis should be constantly modified/supplemented and improved in the practical process, which is a major characteristic of non-standard design.

Information (analysis/summarization) → initial base model (modification/supplementation) → base model

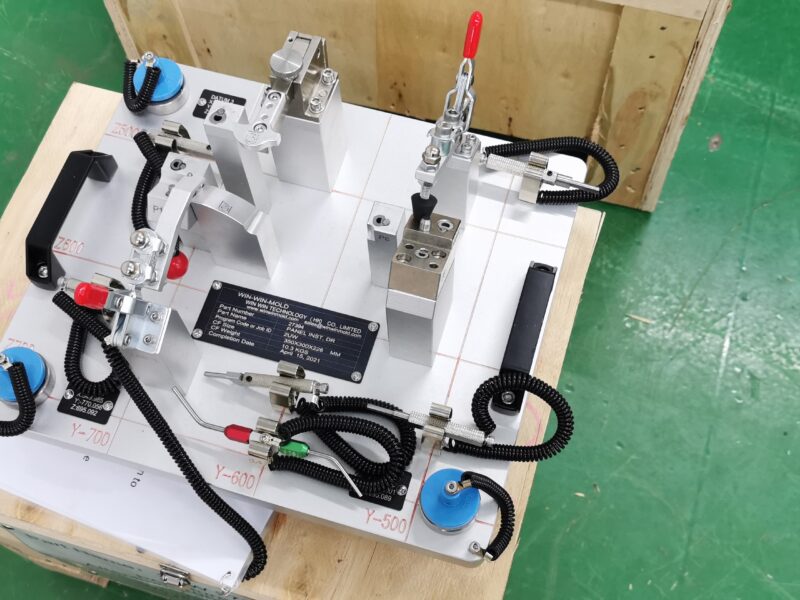

As shown in Figure 1, the fixture body can be initially defined as rectangular body, round body, box body, T-shaped body, cylinder body and rotary body (single arm and double arm) through analysis and generalization.

2, the determination of the basic parameters

Determine the basic parameters of the base type, to capture two aspects: parameters are representative and parameter integrity:.

Each part has many parameters, before parameterization, to optimize all the parameters, can not just give the size label, to use the simplest labeling method to reflect the size of the part of the parties change, but not to miss the size or repeated labeling.

3、Determine the size of the base type and grade difference

Determine the size of the base type is also the parameters of the series, determine the extreme difference is also the parameterization of the parameters of the size of the grade change, so that these dimensions and extreme difference can reflect the changes in the base type as far as possible. For example, when determining the size of the body.

The body’s length, width and other external dimensions, according to the machine table shape to determine. The size of the connection slot to determine the size of the T-slot according to the machine tool, the height of the body (box body) to determine the distance from the main axis of the machine tool to the table, casting rounding to determine the requirements of the casting process.

The poles should be preferably selected according to the collected information, and try to make the poles represent the changes of the base type, and the poles should change with certain regularity, such as by equivariance series, etc. Make parts parameterization, systematization and standardization.

4、Determine the structure of non-standard parts

After the modular design of non-standard parts, it is similar to a standard part, which will be mass-produced later. Therefore, to optimize the structure of these non-standard parts, we have to carry out reliability design and finite element analysis for some key parts in these non-standard parts.

Relieve the worries. At the same time, various needs in terms of process have to be taken into account for easy processing and maintenance. Finally, the dimensions are processed so that they meet the requirements of rounding and standardization and systematization.

So far, the modular design of non-standard parts has been completed. When establishing the library, we can establish the library of non-standard parts like the library of standard parts, extending the practical field of CAD and laying a good foundation for further improving the design efficiency.