Suitable for high-volume processing of CNC machine tool fixtures

High-volume machining cycle = machining waiting time + workpiece machining time + production preparation time “machining waiting time” mainly includes workpiece clamping and tool change time. Traditional manual machine tool fixture “workpiece clamping time” can reach 10-30% of the high-volume machining cycle, so “workpiece clamping” has become a key factor affecting productivity, but also the machine tool fixture “tapping potential “the key object. Therefore, high-volume processing should be used for rapid positioning, rapid clamping (release) of special fixtures, priority can be given to the following three types of machine tool fixtures.

Hydraulic / pneumatic fixture

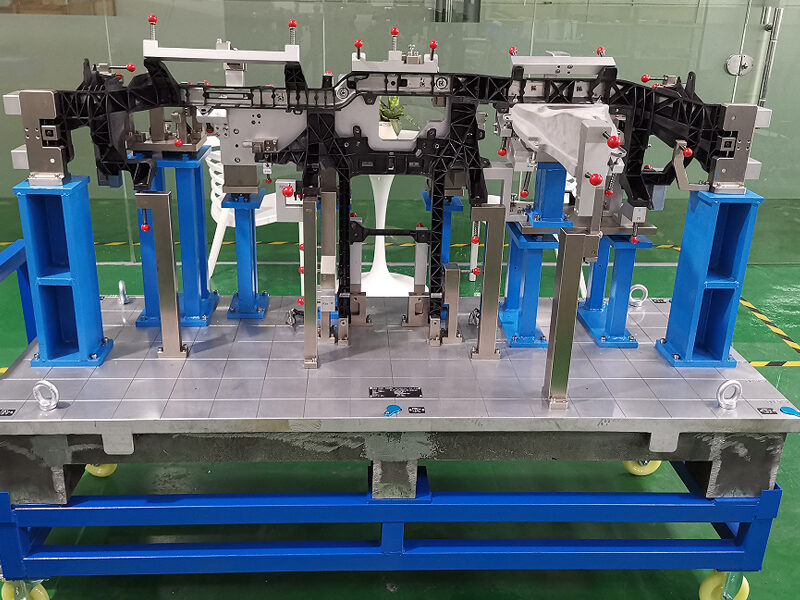

Hydraulic / pneumatic fixtures are hydraulic or pneumatic pressure as a power source, through the hydraulic components or pneumatic components to achieve the positioning of the workpiece, support and compression of the special fixture.

Hydraulic/pneumatic fixture can accurately and quickly determine the mutual position between the workpiece and machine tool and tool, and the position accuracy of the workpiece is guaranteed by the fixture, so the machining accuracy is high; the positioning and clamping process is rapid, which greatly saves the time of clamping and releasing the workpiece; at the same time, it has the advantages of compact structure, multi-station clamping, high-speed heavy cutting, and automatic control, etc.

The above advantages of hydraulic/pneumatic fixtures make them especially suitable for use in CNC machine tools, machining centers, flexible production lines, and especially for mass processing.

Electro-permanent magnetic fixture

EPM clamping has the advantages of fast clamping, easy to achieve multi-station clamping, one clamping can be multi-face processing, clamping smooth and reliable, energy saving and environmental protection, automatic control, etc. Compared with conventional machine tool clamps, EPM clamps can significantly reduce clamping time, reduce the number of clamping times and improve clamping efficiency, so they are not only suitable for small batch production but also for large batch production.

Smooth surface fixture base

Smooth fixture base is not much used in China, but it is widely used in Europe, America and other industrial countries. It is in fact the finishing of the fixture substrate fine blank, components and machine positioning connection part and parts in the fixture positioning surface has been finished. Users can make their own special fixture according to their actual needs.

Smooth fixture base can effectively shorten the cycle time of manufacturing special fixtures and reduce production preparation time, thus shortening the cycle time of mass production in general and improving production efficiency; at the same time, it can reduce the manufacturing cost of special fixtures. Therefore, it is especially suitable for high volume production with tight cycle time.