Fixture is a kind of technological equipment for clamping workpieces. It is widely used in machining, heat treatment, assembly, welding and testing.

Clamps used on metal cutting machine tools are collectively referred to as machine tool clamps. In modern production, machine tool fixture is an indispensable process equipment, which directly affects the precision of workpiece processing, labor productivity and product manufacturing cost.

There are many kinds of jigs and fixtures, which can be classified from different angles. Common classification methods are as follows.

(1) Classification according to the use characteristics of fixtures

According to the general characteristics of jigs in different production types, machine tool jigs can be divided into five categories: general jigs, special jigs, adjustable jigs, modular jigs and assembly jigs.

① Universal fixture

The standardized fixture that can process different workpieces within a certain range is called universal fixture. Its structure and size have been standardized and have certain universality, such as three jaw self centering chuck, flat jaw vise for machine tools, four jaw single action chuck, bench vise, universal indexing head, top tip, center frame and magnetic workbench. This kind of fixture has strong adaptability and can be used to clamp various workpieces within a certain shape and size range. These fixtures have been manufactured and supplied by specialized factories as machine tool accessories, and only need to be purchased. Its disadvantage is that the precision of the fixture is not high, the productivity is also low, and it is difficult to clamp workpieces with complex shapes, so it is generally suitable for single piece small batch production.

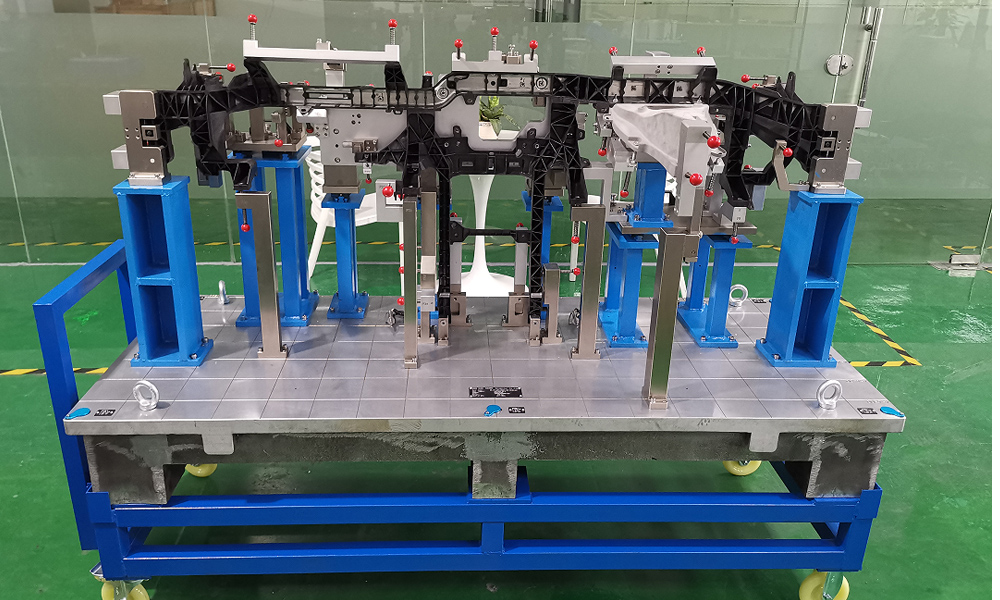

② Special clamp

The fixture specially designed and manufactured for a certain process of a workpiece is called special fixture. In the production of relatively stable products and large batches, high productivity and processing accuracy can be obtained by using various special fixtures. The design cycle of special fixture is long and the investment is large.

Special fixtures are generally used in batch production. In addition to mass production, some special fixtures are also required for medium and small batch production, but specific technical and economic analysis is required for structural design.

③ Adjustable clamp

Some elements can be adjusted or replaced to adapt to a variety of workpiece processing fixtures, known as adjustable fixtures. Adjustable fixture is a new type of fixture developed for the defects of general fixture and special fixture. For workpieces of different types and sizes, it is only necessary to adjust or replace individual positioning elements and clamping elements on the original fixture. Generally, it can be divided into two types: general adjustable fixture and group fixture. The general scope of the former is larger than that of the general fixture; The latter is a kind of special adjustable fixture, which is designed according to the group principle and can process a family of similar workpieces, so it has good economic effect when used in multi variety, medium and small batch production.

④ Modular fixture

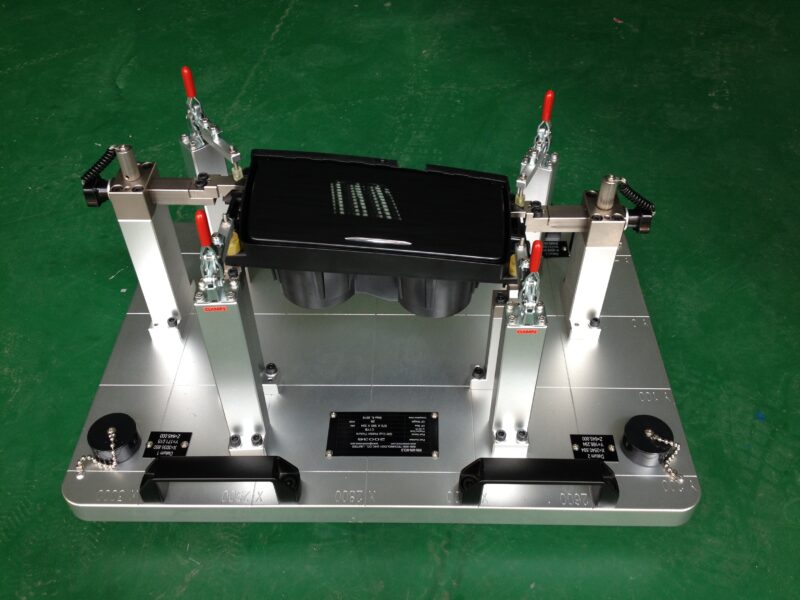

The fixture that adopts standard combination components and parts and is specially assembled for a certain process of a certain workpiece is called combination fixture. Modular fixture is a modular fixture. The standard modular components have high precision and wear resistance, and can be assembled into various fixtures. The fixture can be disassembled after use, and left for new fixture assembly after cleaning. Because the use of modular fixture can shorten the production preparation cycle, the components can be used repeatedly, and has the advantages of reducing the number of special fixtures, etc., the modular fixture is a more economical fixture in single piece, medium and small batch multi variety production and NC processing.

⑤ Assembly jig

Jigs assembled with specialized standardized and serialized assembly parts are called assembly jigs. It has the advantages of modular fixture, but it has higher precision, higher efficiency and compact structure than modular fixture. Its base plate and clamping components are often equipped with small hydraulic cylinders. This kind of fixture is more suitable for use on CNC machine tools.

(2) Classification of machine tools

Fixtures can be divided into lathe clamps, milling machine clamps, drilling machine clamps, boring machine clamps, gear machine tool clamps, CNC machine tool clamps, automatic machine tool clamps, automatic line following clamps and other machine tool clamps according to different machine tools.

(3) Classification by power source of clamping

According to the power source of clamping, clamps can be divided into manual clamps, pneumatic clamps, hydraulic clamps, gas-liquid force boosting clamps, electromagnetic clamps and vacuum clamps.