Wave soldering fixture storage methods and disposal standards

For wave soldering jigs in use, the following points should be noted in order to improve the life of the jigs and ensure the quality of welding.

1) Before the fixture comes into contact with the wave, it should be preheated by the preheating unit to avoid direct contact with thermal shock of higher temperature.

2) In the process of taking the fixture, it should be taken lightly to avoid improper external damage to the fixture.

3) Avoid contact with strong acid and alkali, it is recommended to use neutral solder; avoid wiping the fixture with alcohol or other organic solvents, it is recommended to use saponifier, and put it into the ultrasonic cleaner for cleaning.

4) When multiple jigs pass through the wave, ensure a certain distance between them to prevent collision.

5) When using lead-free brazing solder, use the lead-free wave soldering jig to match it.

6) For some more precise fixtures, it is recommended to use anti-vibration carts when transporting within the workshop.

7) For PCB board fastening screws, clips, pressure blocks, pressure bars and other fixed structures, should be regularly checked to prevent loosening phenomenon.

8) Wave soldering fixtures are generally stored in a vertical manner. When stored horizontally, the lower fixture will be deformed due to excessive weight.

The maintenance frequency of the fixture is as follows.

1) Daily maintenance: jig supporters check all jigs on the production line and correct them in time if there are abnormalities.

2) Bi-weekly maintenance: The person in charge of the fixture and the operator on the production line will do it together.

3) Quarterly maintenance: done by the person in charge of the fixture.

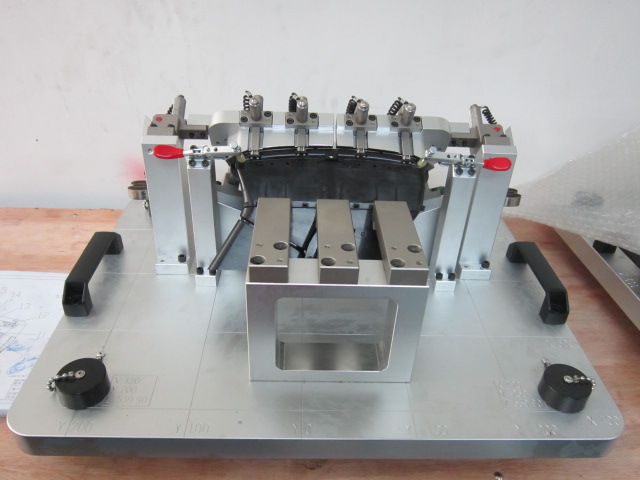

Disposal standard of wave soldering fixture

When wave soldering products have multiple quality problems, the process of wave soldering must be analyzed first. When the possibility that the process problem causes the degradation of welding quality is excluded, the jig used can be tested. When the fixture has the following problems, and it is not easy to repair, you can consider applying for fixture scrapping.

1) Use vernier calipers to measure the distance from the outer frame around to the horizontal table of the clamp, if the absolute value of the difference between the maximum value and the minimum value is greater than 1.5mm, you can apply for scrapping.

2) Put the PCB into the corresponding jig, measure the gap between PCB and jig with a stopper, when the absolute value of the difference between the maximum and minimum value of the gap is greater than 1.5mm, you can apply for scrap.

3) When the inner frame of the fixture is seriously damaged and cannot be repaired, and the product soldering quality is seriously degraded, it can be applied for scrapping.

4) When the inner frame of the fixture is damaged beyond repair and the soldering quality of the product is seriously degraded, it can be applied for scrapping.

5) For PCB products that are no longer in production or jigs that have been discontinued for more than six months, you can apply for scrapping.