What are the uses of precision check fixtures and measuring brackets?

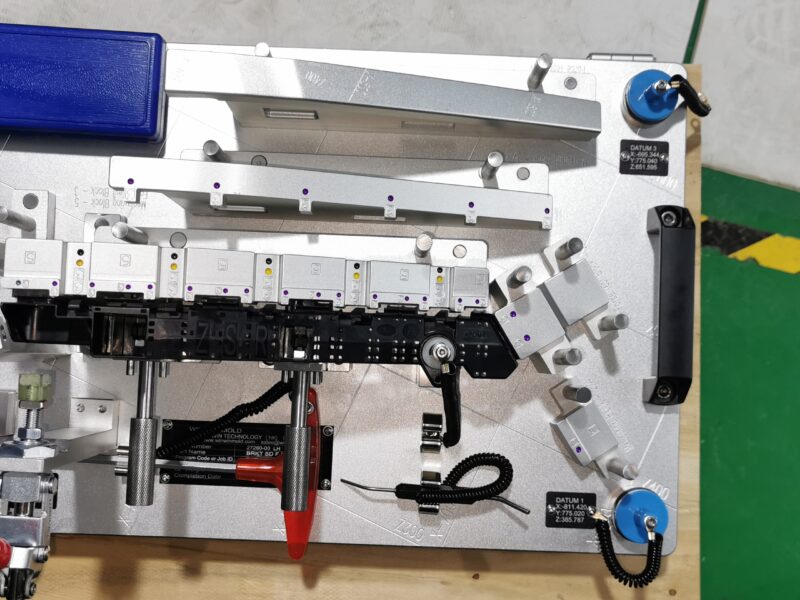

Check fixture is a special testing equipment used to measure and evaluate the size and quality of parts. It is a simple tool used by industrial production enterprises to control product size (such as aperture, space size, etc.), improve production efficiency and control quality. It is suitable for products produced in large quantities (such as automobile parts) to replace professional measuring tools (such as caliper micrometer three dimensional).

Sometimes the check fixture will also be considered as a measuring support when designing the structure. However, when the online inspection function of the check fixture and the function of the measuring bracket cannot be met together, the online inspection function of the check fixture should be met first.

The measuring support is a kind of auxiliary support when measuring parts are tested in three coordinates using a three coordinate measuring machine. All supporting surfaces (points) and locating datum surfaces (points) must be milled according to the CAD data of the parts. The measuring brackets of some special parts should also have the function of partial check fixture.